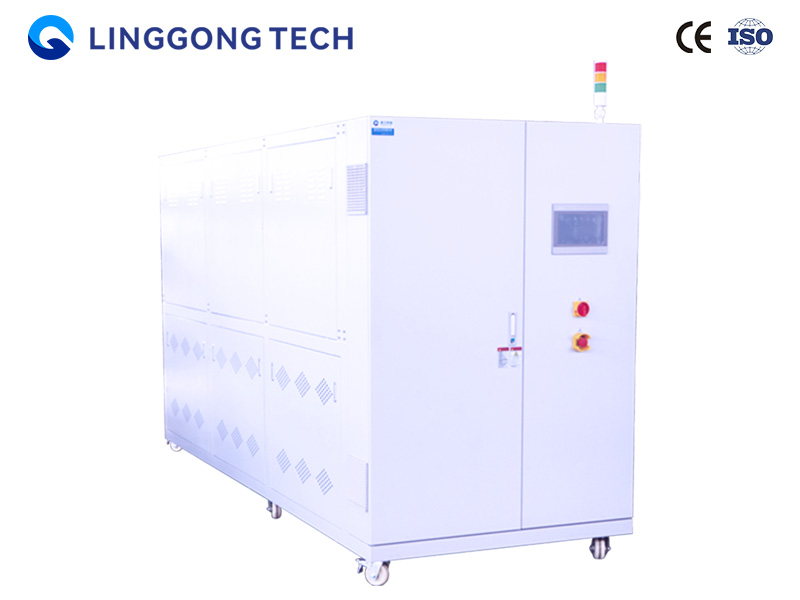

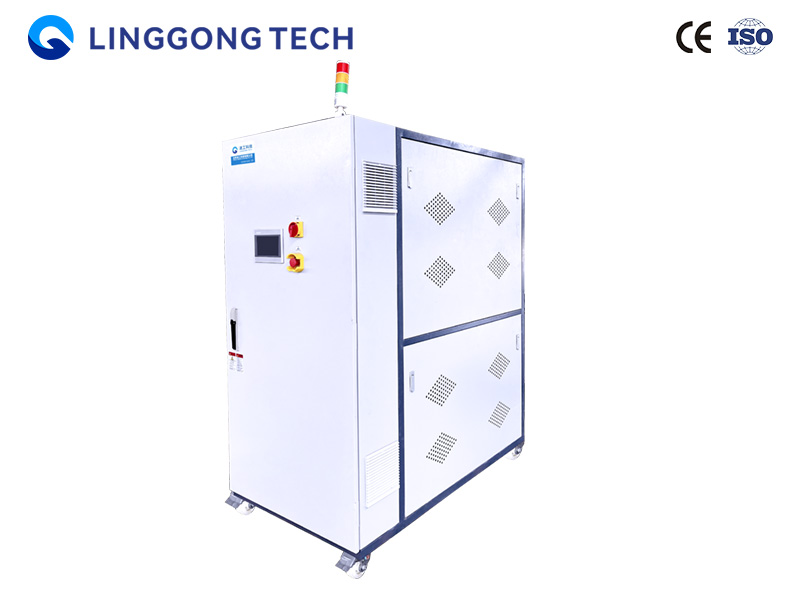

Normal-Temperature Control System

With the progress in new energy vehicle industry, the requirements for temperature control test technology have been put forward. In order to adapt to the new requirements for temperature control test,the coolant temperature control devices is specially developed for the electric vehicle to simulate different work conditions of new energy vehicle with mounted liquid cooling system.It can not only test the high-temperature and low-temperature tolerance,the heat dissipation efficiency, flow resistance,pressure resistance, reliability and performance parameters of relevant vehicle components.

Normal Temperature Series (Temperature Control Range 5~85℃,Flow control, Pressure Control)

Cooling power range: 02KW--20KW.

Temperature control range: 5--85℃.

Flow control range:2-20L/min.

Heating power:

Output channel: 1,supporting multiple channels.

The conditioning devices is developed to supply the coolant maintained at a specific temperatures and flow volume to the test item.They can be devided into air-cooled type and water-cooled type according to the type of devices' heat dissipation towards the environment.The water-cool type are designed with two circuits,the coolant circuit(referred as primary circuit) and the cooling water circuit(secondary circuit) repespectively. The conditioned coolant is delivered to the test item and returns to the devices. The cooling water from the facility is fed into the devices and returns to the facility. The air-cooled type differ in the secondary circuit where the heat dissipation medium is air.

Descriptions

The conditioning unit is designed as a mobile unit with a cold-storage liquid tank.The coolant in the test item circuit is conditioned either by electric heaters or by refrigeration circuit. The device is sealed against the escape of liquid media.

The conditioning devices support multi-channel temperature control.The conditioned coolant is delivered to different test object.

There are two options.

Option 1: the temperature is same and the flow rate and pressure are controlled independently.

Option 2: the temperature, flow rate and the pressure are controlled independently.

Test System Overview

The test item is connected to a test platform adapter.The conditioning device deliver the coolant with a specific temperature and flow rate inside of the test item.The test item will go through the diffierent temperature changes. The conditioning unit will monitor and measure Temperature, Flow Rate and Pressure of the coolant and compress air. After the test,the coolant can be pruged from the test item to the conditioning test.

Test System Overview

1.Adjustable and controlled in the whole temperatrue range of -40℃~120℃(can be extented);

2. Equipped with various of protective measures for safety assurance;

3. Control panel with large size, combined with PC remote intellegent control,easy to operation;

4.Support multiple communication modes ;

5. Components using well-known brands ;

6. Easy to install,provide installation&commissioning, operation and maintenance training.

General Specifications | |||||||

Model | LQ02K | LQ05K | LQ7500 | LQ10K | LQ15K | LQ20K | |

LQ10k-2L | LQ15k-2L | LQ20K-2L | |||||

LQ20K-3L | |||||||

Temp.Range | 5℃~+85℃ | 5℃~+85℃ | 5℃~+85℃ | 5℃~+85℃ | 5℃~+85℃ | 5℃~+85℃ | |

Temp.control accuracy | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | |

Number of fluid output channels | 1 | 1 | 1 | 1 | 1 | 1 | |

2 | |||||||

2 | 2 | 3 | |||||

Flow control range per channel | 2~25 L/min | 2~25 Lmin | 2~26 Lmin | 2~25L/min | 5~50 L/min | 5~50 L/min | |

Flow control accuracy | ±0.2L | ±0.2L | ±0.2L | ±0.2L | ±0.2L | ±0.2L | |

Heating power | 3kW | 6kW | 10.5kW | 10.5kW | 13.5kW | 13.5kW | |

cooling capacity | 100℃ | 2kW | 5kW | 7.5kW | 10kW | 15kW | 20kW |

20℃ | 2kW | 5kW | 7.5kW | 10kW | 15kW | 20kW | |

5℃ | 3kW | 6kW | 10.5kW | 10.5kW | 13.5kW | 13.5kW | |

Operation display size | 7 inch color touch screen | ||||||

Communication | Modbus RTU protocol RS485interface,optional CANcommunication bus,Ethernet interface TCP/IP protocol | ||||||

Safety protection | With self-diagnosis function;Refrigerator overload protection;High pressure switch,overload relay,thermal protection | ||||||

device,low liquid level protection,high temperature protection,sensor fault protection and other safety functions | |||||||

refrigerant | R407C、R134A、R454C、R454B、R32 | ||||||

Connection size to the test item | |||||||

Cooling water at 20C° | ≤32℃ | ≤32℃ | ≤32℃ | ≤32℃ | ≤32℃ | ≤32℃ | |

Power 380V50HZ | 5kW | 11kW | 21kW | 23kW | 25kW | 30kW | |

Dimension cm | 600*500*900 | 975*600*1200 | 1350*800*1850 | 1250*750*1900 | 1900*900*2000 | 1500*750*1900 | |

1350*800*1850 | 1350*900*1900 | 1500*850*1900 | |||||

1600*900*1900 | |||||||

Optional | purging function, automatic refill liquid fucntion, cooling power adjustable | ||||||